I have almost all the colors with names for my kids. I like the bright, pop of color.

*The link is to the latest version of Straits Organic that was recommended to me. The color range has changed from the previous version.

- TOP

- About us

- Ikeuchi's people

- Production optimization and visualization of production processes

Vol.11

Production optimization and visualization of production processes

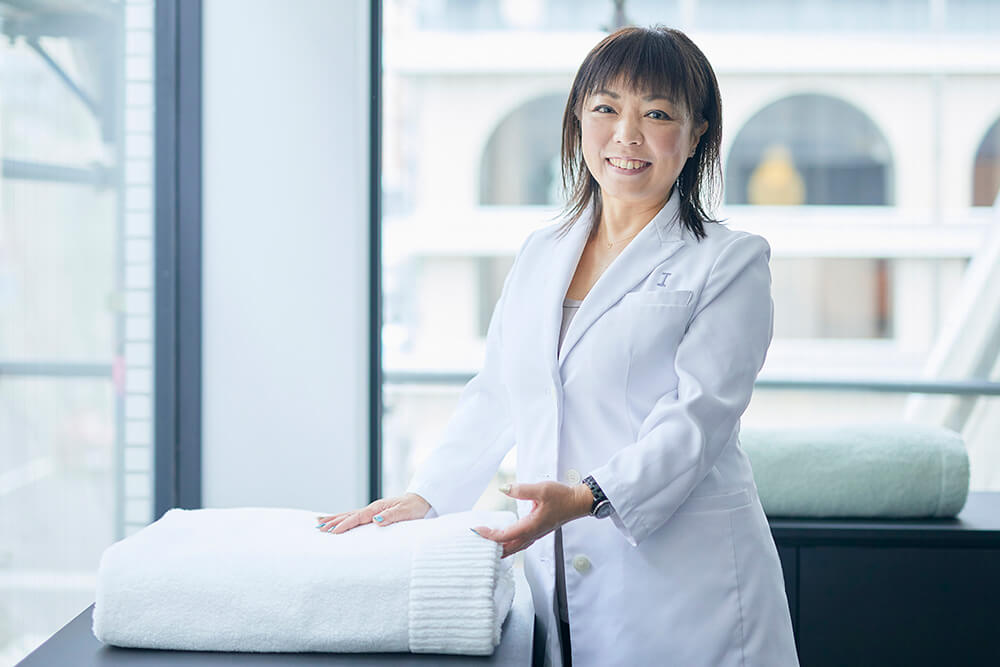

IKEUCHI ORGANIC is both a manufacturer and retailer, and the Production Department has been faced with the challenge of producing a wide variety of products in small lots in a short period of time while maintaining quality, as the company has shifted its focus from mass production with sales staff taking large orders to direct original retail sales. Mr. Watanabe, head of the Production Department, who manages production, and Mr. Kurobuchi, who records and incorporates traceability data into a system that records and makes available the history from yarn to finished product, spoke about the challenges IKEUCHI ORGANIC faces and its current efforts.

Head of Production Department Watanabe/Kurofuchi

It’s been 13 years since I joined the company, and unifying shipping standards as IKEUCHI ORGANIC is a challenge!

–Mr. Watanabe, please tell us about your job in production control.

Watanabe: Even though I say production management, I did not come to my current position after learning about it (production management), but rather I was suddenly assigned to it. But my seniors told me at that time that there are professionals in each department. So I was told that I should leave the basic things to the professionals, and just pick up the important parts as I went along. Well, I’ve been content with that up to now… (laughs).

–(laugh)… (laugh).

Watanabe: There is a shortage of people. There are not many true professionals. I have been with this company for 13 years, plus I am using my past experience to establish IKEUCHI ORGANIC’s inspection and shipping standards. (Mr. Hashida, the head of the Production Engineering Office, also advised me to focus on sewing, inspection, and shipping, since there are veterans in the area of suture preparation, weaving, and other factory-related matters, and there are people who can take charge if we are there.

When you do something new, you have to suffer.

–What are some of the issues and points for improvement that you can see from your current position in production management?

Watanabe: In the end, we need to bring production in-house. We can’t manage the schedule because more than half of it depends on the arrangements made by the subcontractors. That is why our future challenge is to promote in-house production. Right now, it’s a bit of a struggle. We are working with a consultant to shorten the lead time, and we are trying to find ways to turn things around quickly ( *1), but our facilities are not keeping up…. I am struggling with the gap there, but the president says, “When you do something new, you have to start with suffering,” so I have given up on that (laughs). He says it never gets easier (laughs).

–(laughs). – In the case of production, it’s like we can’t stand up for ourselves if we stand up for that side….

Watanabe: There is a problem with the loom that is holding up the originals. If this is not improved, there is nothing we can do. In the end, you may think that everyone should weave on two or three shifts, but what are we going to do in the middle of the night to weave on one or two looms? It would be like asking, “What do we have to do to run one or two looms? (If we do not process the yarn in time, it will be the same as if the next weaving line does not come in time. I would like to do my best to shorten the lead time. Another thing is 5S ( *2). We also need to continue our ISO activities, so that’s about all I can say.

I want to make the information that everyone wants visible in a flash.

–Mr. Kurobuchi, please tell us about your current work.

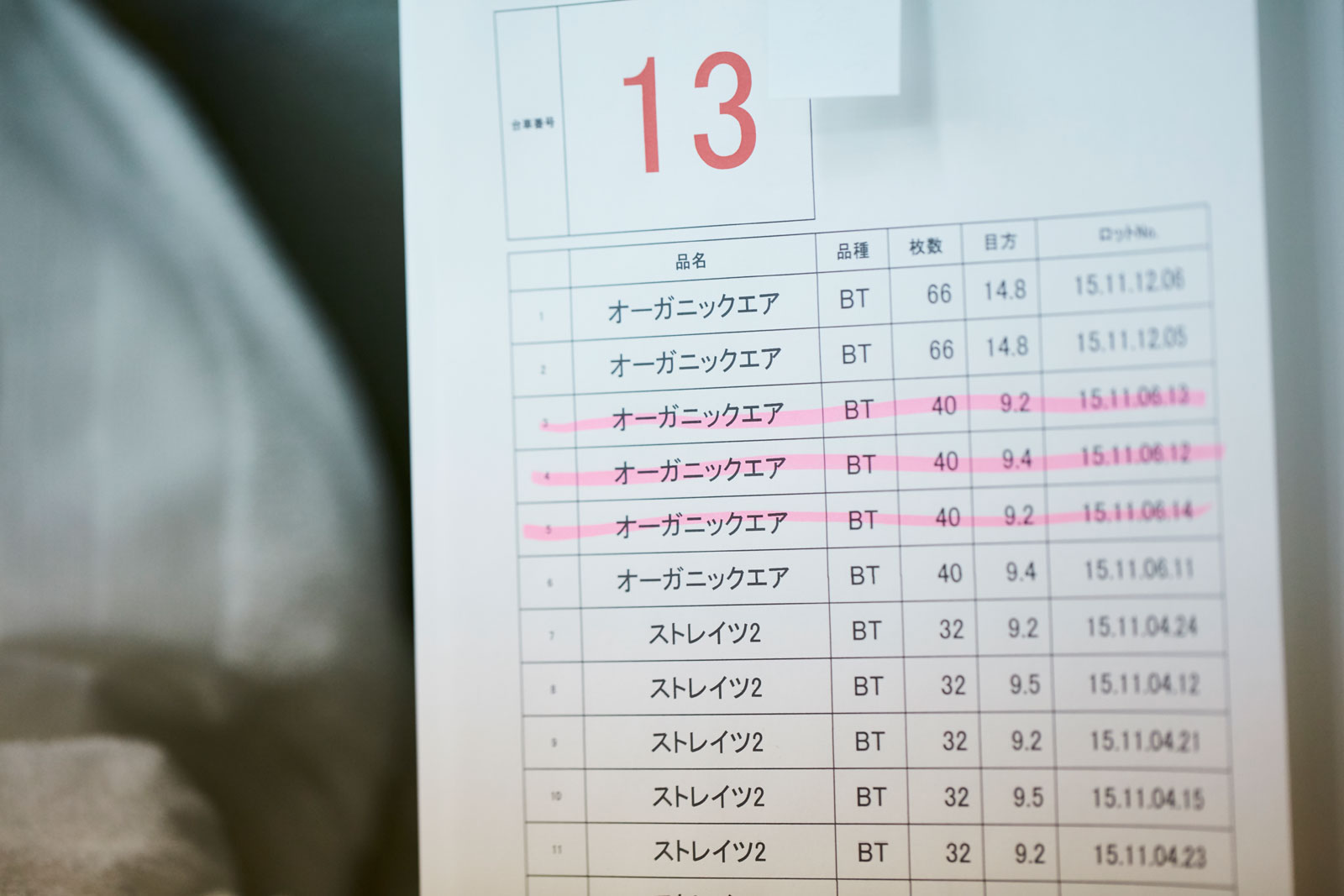

Kurobuchi: The company has acquired ISO 22000 certification (*3), and we have data on traceability (which we have to do) and what kind of yarn our products are made from… so I manage or rather check the flow of goods in and out of the factory.

–Do you find anything rewarding about your job?

Kurobuchi: I haven’t reached the point where I find it rewarding yet, but what I think about most is that I want to make the information that everyone wants visible. What I want most is to make the information that people want visible in a flash. I think this is a very difficult task, but I would like to collect data to make it go smoothly, and since I am only able to do the tedious work, I would like to do something that would be good for the company. I hope I can do something that will be good for the company.

–Director Watanabe: From your point of view, how do you feel about Mr. Kurobuchi’s work?

Watanabe: I rely on her a lot. I tell her to make materials that I cannot make. I have to tell her everything I don’t want to say, even if I really don’t want to say it, such as that something is not done here, and I have to go over every detail of the inventory. I am very grateful to her for taking care of these tasks, and I am very impressed that she makes an effort to put in accurate and precise figures. Without him, I don’t think I would have been able to do the traceability by myself, and I am glad that the timing of the start of traceability coincided well with the end of my maternity leave ( *4).

I have almost all Straits Organic towels in all colors with my name on them.

–Lastly, let’s start with your favorite towel, Mr. Watanabe.

Watanabe : (Holding the Straits Organic that I brought with me) I like it myself, or rather, my child has always had one in almost every color with his name on it. I put my name on it, and since ours doesn’t have any colors or patterns, I think it is easier for my child to hold it if it has a pattern or a bright pop of color, so I let her have Straights Organic.

–How many years have you been using it?

Watanabe: Well, this is about the fifth year.

–I can’t believe it’s been five years. How often do you use it?

Watanabe: I use it about once a week because there are so many colors.

Organic Air that children touch and thrash

–Kurobuchi-san, please tell us about the towel you recommend.

Kurobuchi : It is Organic Air. I had the opportunity to make the president’s pajamas, and when I was sewing them, I was thinking how warm this fabric is. My children don’t like blankets in the summer because they are too heavy and they kick them, but this Air is light and they don’t feel like they are being covered, so they are cool in the summer and warm in the winter. (Laughs.) The children say, “Fluffy, isn’t it? (laughs).

(laughs) — Does your child use only IKEUCHI towels?

Kurobuchi: Yes, they are. I take one to the day-care center as a futon, and everyone touches it like this. It’s so soft! Everyone brings one with a color on it, but my child is plain (laughs), like brown. But they (the other children at the school) touch them and rub them (laughs). I think children really like the essence of the texture, the feel, the touch, and so on.

Interview January 2016

Interview and text by Mutaguchi, Kamio

Photographer/ Yuji Kimura (Kimura Photo Office)

Notes

*1: Working with an outside consultant to improve delivery times for small lots

*2: Improvement items for the workplace environment, named after the initial letters of “Seiri,” “Seiton,” “Seiso,” “Seisou,” “Seiketsu,” and “Shitsuke.

3: Third-party certification system for food safety management systems

4: Ms. Kurobuchi is currently back at work after taking maternity leave when she gave birth.

Recommended towels:[Straits Organic 240].

Head of Production Department Watanabe/Kurofuchi

Ikeuchi's people

-

Vol.56

We want you to use our online store as if you had visited the store.

We interviewed Mr. Ishikawa, who is in charge of customer support and shipping management to attend to customer requests and inquiries received at the online store.

Web Customer support and shipping management Ishikawa

-

Vol.55

From a fan to an employee. Deliver what you love to as many people as possible.

Ms. Minami has been a fan of IKEUCHI since she was a student, participating in open houses. We asked him to tell us why he applied to become an employee and what he hopes to achieve in the future.

Tokyo Store South

-

Vol.54

We want to be a place where all people can feel light and hope.

Mr. Masuda, who is in charge of both stores as sales conductor and store manager, talked about what the stores are aiming for.

Sales Conductor/Store Manager Masuda