I like this one because although I use almost all kinds, I still prefer it to be a little thicker.

- TOP

- About us

- Ikeuchi's people

- 15 years of history with thread

Vol.13

15 years of history with thread

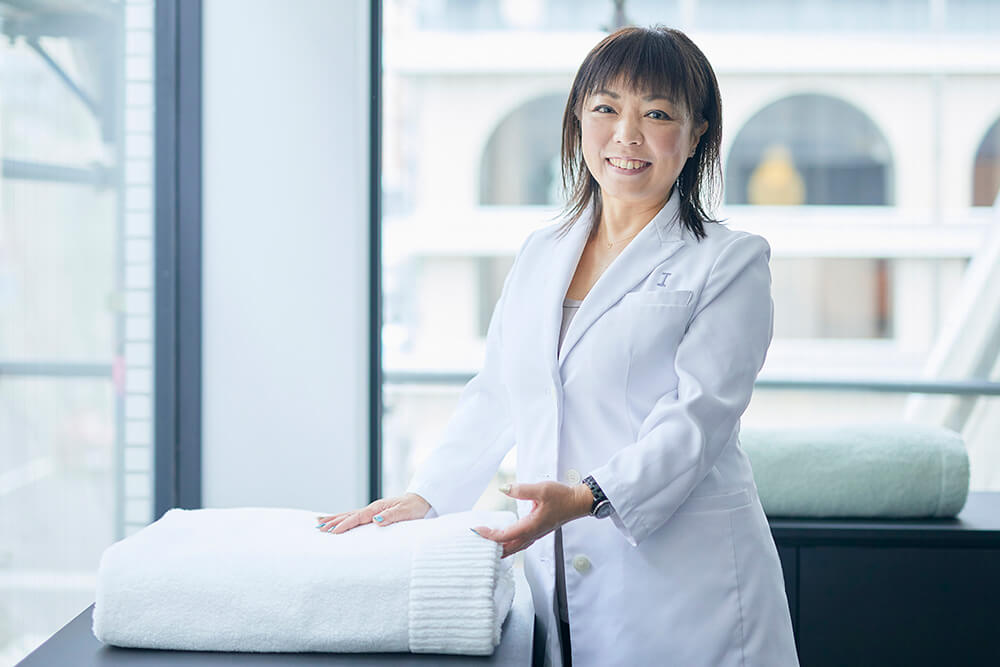

Mr. Shibata is in charge of arranging the yarn used in IKEUCHI ORGANIC. He is a specialist in yarn, the raw material for towels, including communication with cooperating companies in yarn processing. For this interview, we spoke with him while he was winding yarn. With a quiet atmosphere and a simple tone of voice, he talked about the events of IKEUCHI ORGANIC and towels that have occurred during his long career at the company.

Production Manager Shibata

Taking care of the yarn and preparing it for reuse.

–What are you doing at the moment?

We usually have about 1 kg of yarn, but after we use it, we are not able to use it all because there will be leftovers of this size (while showing the thinner cheese ( *1) ), so we are making it bigger and reusing it again.

-Is there any particular problem with connecting the threads and rewinding them?

Well, not very well. The joints are inevitable, and there is a possibility that the product will be a “B” product. That said, it’s not like there are dozens of places in a single towel.

–How long does it take to wind one?

(It depends on the yarn count ( *2), but it takes about an hour for yarn like Organic 120. It depends on the speed of the winder.

From a Handkerchief Factory to a Focus on Originals

–How many years ago did you join IKEUCHI ORGANIC?

Fourteen or five years ago.

–Have you been in your current job ever since you joined the company?

I was originally assigned to the sales planning section, and although the people (other employees) have changed, what I do hasn’t changed that much.

–What would you describe your job as?

I guess it would be easier to say arranging materials and yarn.

–I guess you have seen the company change over the past 14 or 5 years, and you have seen many aspects of the company change?

Well, when I say it has changed, it has changed. When I entered the company, handkerchiefs were still the main product, and the number of people (employees) might be about the same as now, but we were still working two shifts.

–Did the factory at that time operate at full capacity day and night?

There were enough people working the night shift. Looms were different from today, and there were five looms for handkerchiefs. The year before last, we disposed of six Eight ( *3) looms, but there used to be more Eight looms than Eight. After the civil rehabilitation ( *4), the organization changed and we started to focus on originals.

The president declared that he would make towels made of 100% organic cotton

–What did you think when you heard that the company was going through civil rehabilitation?

I don’t know what to think, but I wondered what we would do since we didn’t have handkerchiefs at that time (before the civil rehabilitation, handkerchiefs accounted for 70% of orders). When the company was under civil rehabilitation, I was doing something like cleaning up the rest, but gradually the ratio with the originals started to change. I remember the president talking to me and saying, “Starting this year, we’re going to make towels made of 100% organic cotton.

Cotton Nouveau passed the test.

–What is your favorite IKEUCHI ORGANIC towel?

Cotton Nouveau. Well, I use Organic 316 and so on, but I prefer towels with a little thickness. I get them as year-end gifts from the company ( *5). I use almost all of them, but I can’t say which ones I use. However, when I use towels from other companies, I sometimes think they are not as good as ours. There is no doubt about that.

–Do you have any criteria for your favorite towels?

Not really. As long as they are not strange towels.

–I have a feeling that your standard for “strange” is much higher than others.

Maybe (laughs). Cotton Nouveau is acceptable for normal use.

Interview January 2016

Interview and text by Mutaguchi, Kamio

Photographer/ Yuji Kimura (Kimura Photo Office)

Notes

*1: A cylindrical piece of string wound around a wooden tube that serves as the core. Derived from its resemblance to the food cheese.

*2: A unit for expressing the thickness of thread. The larger the number, the finer the thread.

3: A famous weaving machine manufactured by Toyoda Automatic Loom Works, the originator of Toyota Motor Corporation, which was introduced in the 1970s.

4: In 2003, a business partner on which Toyota Motor Corporation depended for more than 70% of its sales suddenly went bankrupt, incurring debts of up to 1 billion yen and filing for civil rehabilitation.

*5: The company provides towels as year-end gifts to employees at the end of the year.

Recommended towels:Cotton nouveau

Production Manager Shibata

Ikeuchi's people

-

Vol.56

We want you to use our online store as if you had visited the store.

We interviewed Mr. Ishikawa, who is in charge of customer support and shipping management to attend to customer requests and inquiries received at the online store.

Web Customer support and shipping management Ishikawa

-

Vol.55

From a fan to an employee. Deliver what you love to as many people as possible.

Ms. Minami has been a fan of IKEUCHI since she was a student, participating in open houses. We asked him to tell us why he applied to become an employee and what he hopes to achieve in the future.

Tokyo Store South

-

Vol.54

We want to be a place where all people can feel light and hope.

Mr. Masuda, who is in charge of both stores as sales conductor and store manager, talked about what the stores are aiming for.

Sales Conductor/Store Manager Masuda