It was the first towel made.

- TOP

- About us

- Ikeuchi's people

- Unabated inquisitiveness of a towel craftsman with a career spanning more than 40 years

Vol.45

Unabated inquisitiveness of a towel craftsman with a career spanning more than 40 years

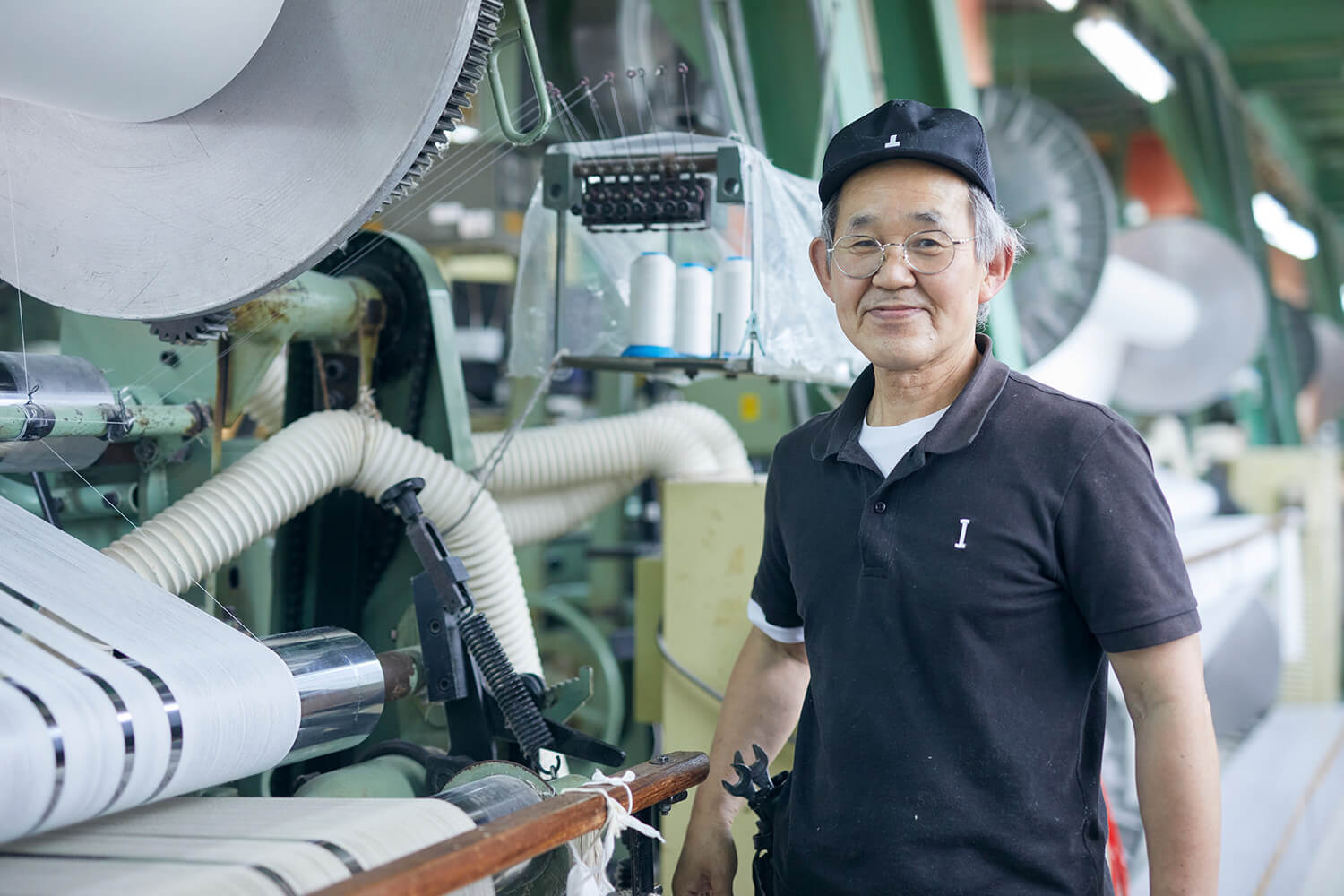

Mr. Abe is one of IKEUCHI ORGANIC's skilled craftsmen. He is the most senior employee of IKEUCHI ORGANIC, except for Mr. Ikeuchi, the company's representative. He has been involved in towel production for a long time and has also been involved in teaching many young craftsmen.

Production Engineering Abe

After various experiences, I joined IKEUCHI ORGANIC

My name is Abe, and I work as a weaver at the Imabari headquarters factory.

When I was a student, I went to a technical high school and studied spinning and weaving. After graduation, I joined a sweater company in Osaka, but when I quit there, I came back to Imabari and joined a towel company. From that point on, I have always been involved in towels.

In the 1990s, I went to China and experienced setting up a towel factory. I did everything from bringing in machines to installing them. After that, I worked as an expatriate and taught the local members how to make towels, but it was not easy because of the difference in language.

Since there were only a few staff members from Japan, I had to deal with everything, whether it was weaving or dyeing. In particular, I was the only loom maintenance worker, so if something went wrong with the machine, I had to deal with it myself or the factory would stop. It was a hectic time, but now I feel it was a valuable experience.

I was thinking about changing jobs to another towel company when I heard about IKEUCHI ORGANIC (Ikeuchi Towel Co. at that time). I was introduced to IKEUCHI ORGANIC by the same vendor who worked at IKEUCHI ORGANIC and at the company I worked for before.

The type of loom is the most important factor in towel production. The loom I had been using until then was a SULZER loom, and since Ikeuchi Towel also used the same loom, I thought I could make use of my past experience, which was the main reason I changed jobs.

That is how I joined Ikeuchi Towel in 1998. At that time, towel handkerchiefs were the main products, and we were also working on products using silk, which was a very different picture from today.

Times have changed since I was a young man.

One of the things that comes with the towel manufacturing business is the technical guidance to younger workers. Including my former company, I have taught more than 100 people about towel making.

When I was young, I rarely received instruction on techniques from my seniors. Basically, it was “watch and learn. I would steal what skilled craftsmen were doing and try to imitate them. Through repetition, I learned one by one.

I wanted to learn the work quickly and become a full-fledged craftsman as soon as possible, and I think I also had a competitive spirit, thinking, “I want to learn before that person does and be better than him. I studied in my own way, dabbled in things I had not been taught, and gradually expanded the scope of my work.

But when I look at young people these days, when it comes to things they have never been taught, they rarely make any moves on their own because they have not been taught. When I see such a figure, I feel that times have changed, for better or worse.

When we were young, when the towel industry was thriving, many young people came to work in one factory, and it was easy for them to naturally develop a competitive spirit. But in a small factory like IKEUCHI ORGANIC, how do you treat people to foster a spirit of inquiry and ambition?

The times and environment are different from when I was there. As a person who teaches work, I feel that I have to keep this in mind and treat young people accordingly.

An inquisitive mind that has yet to wane

Speaking personally, I will soon enter my 70s, but I still intend to work.

Even now, when I touch the loom, I make new discoveries. There are many times when I think it is getting out of tune and I adjust it the same way I always do, but it doesn’t work as well as I would like it to. Each time this happens, I am left scratching my head wondering what to do.

On the other hand, there is a part of me that finds these unexpected situations amusing.

I have loved making things with machines and tools since I was a child, making plastic models of toy cars and remodeling them. Even now, on my days off, I fix furniture at home by myself or build it from scratch.

I guess that’s why towel manufacturing suits me so well. I feel an indescribable sense of fulfillment when I devise my own ideas and the machines work well.

Although I am getting older, I would like to become more knowledgeable about towel manufacturing and to be able to handle the machines better. These are my aspirations.

As a towel craftsman, I feel that I still have room for growth. I would like to become a person who can proudly stand up for himself when people call him a craftsman.

Interview May 2023

Interview and text by Keiji Ide

Photographer: Yuji Kimura

Recommended towels:Organic 120 Bath Towel

Production Engineering Abe

Ikeuchi's people

-

Vol.56

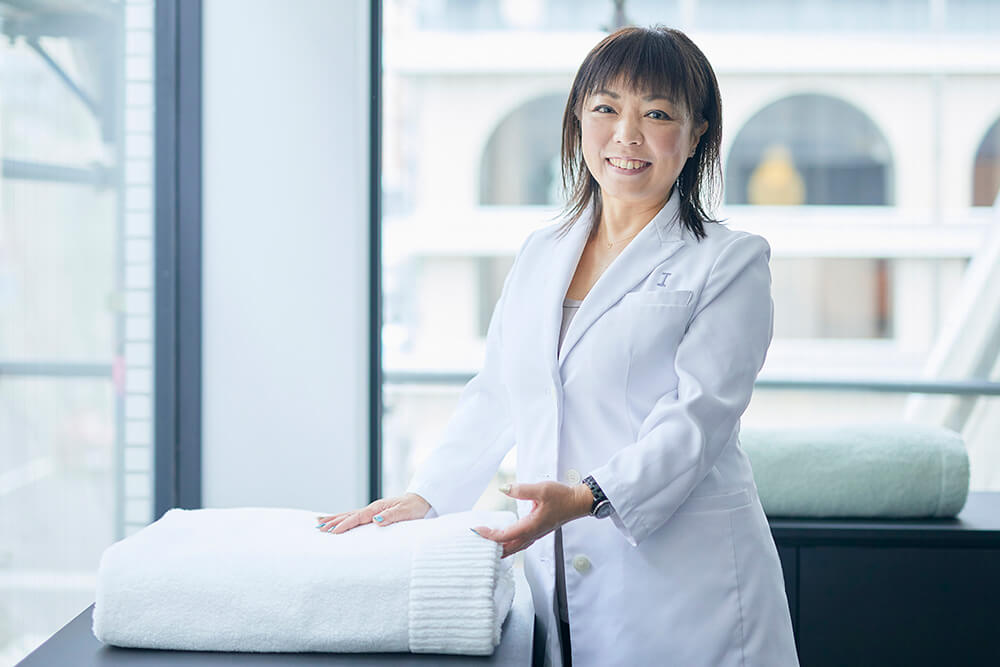

We want you to use our online store as if you had visited the store.

We interviewed Mr. Ishikawa, who is in charge of customer support and shipping management to attend to customer requests and inquiries received at the online store.

Web Customer support and shipping management Ishikawa

-

Vol.55

From a fan to an employee. Deliver what you love to as many people as possible.

Ms. Minami has been a fan of IKEUCHI since she was a student, participating in open houses. We asked him to tell us why he applied to become an employee and what he hopes to achieve in the future.

Tokyo Store South

-

Vol.54

We want to be a place where all people can feel light and hope.

Mr. Masuda, who is in charge of both stores as sales conductor and store manager, talked about what the stores are aiming for.

Sales Conductor/Store Manager Masuda